SICK Hybrid DWS:

Logistics Lector Array Track and Trace System with Dimensioning, Weight Recording, and Advanced Functionality

The Logistics Lector Array Track and Trace System integrates high-speed, image-based code reading and assignment capabilities designed for small object gaps. Utilizing a matrix camera covering up to five sides, the system achieves conveyor speeds of up to 3.0 m/s.

Powered by intelligent, AI-based decoding algorithms, the system excels in reading codes of varying quality, ensuring reliable operation across diverse conditions. Its robust processing power supports rapid conveyor belt speeds, enhancing overall throughput efficiency.

Displayed at CeMAT 2024, the system features 2x LMS500 2D laser scanners for precise dimensioning data acquisition, complemented by weight measurement from the WIPOTEC weighing cell. This integration forms a comprehensive Dimensioning, Weighing, and Scanning (DWS) solution, offering competitive pricing without compromising on precision and adaptability.

What are included in the DWS system on display at cEmat australia 2024

VMS6200

Dynamic volume measurement of objects

Recording basic data correctly and efficiently is of fundamental importance for logistics processes. The ability to determine the weight and dimensions of cube-shaped and irregular objects with transparent, film-wrapped or very dark surfaces is the minimum requirement for this application. Objects with bar codes, matrix codes or RFID tags must also be able to be identified at conveying speeds of up to 4 m/s on flat, tray, and cross-belt conveyor belts. This data enables downstream processes to be carried out reliably, storage space to be optimized, and transport processes to be performed efficiently. Depending on the application, it may be necessary to meet these requirements at ambient temperatures down to −30 °C.

Lector85x

A camera for wide fields of view and large reading distances

Goods shipments in crumpled, reflective packaging can pose problems for laser- or image-based identification systems. Shipments with attached RFID transponders in addition to classic barcodes can be reliably read with the Lecotor85x image-based code reader and RFID technology from SICK. And just one camera covers the entire belt thanks to the large reading field and excellent depth of field. The RFID systems can be combined with optical reading systems in order to identify and complete different shipping label generations with equal reliability.

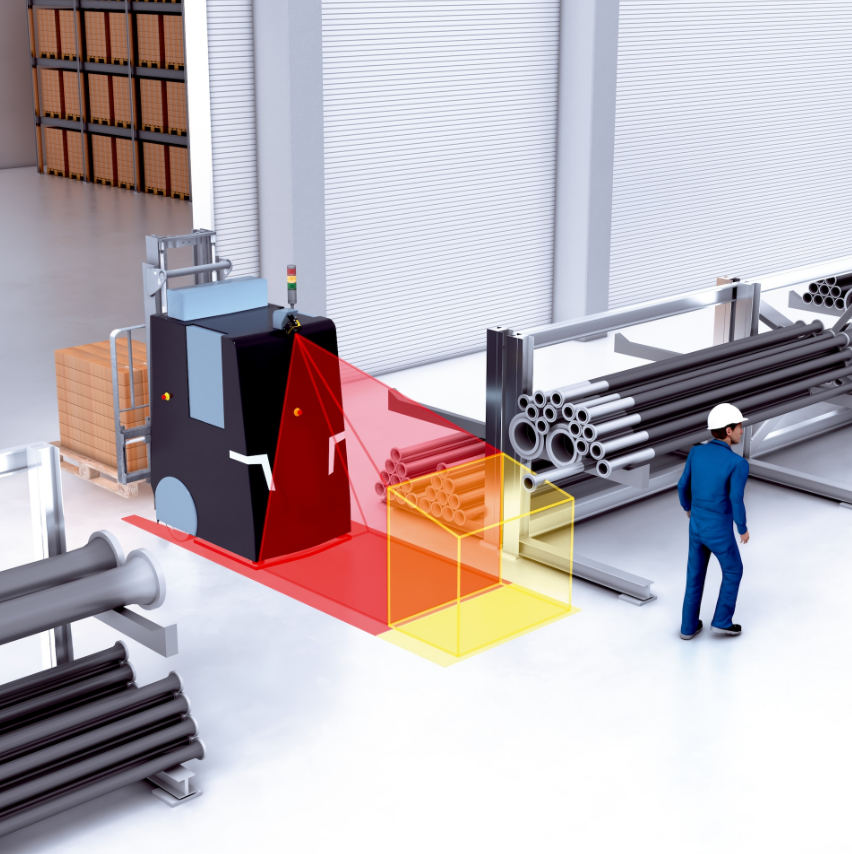

safeVisionary 2

Safe 3D environment perception opens up new dimensions

Safety laser scanners attached to AGVs and AMRs detect people safely to ensure they are protected. However, objects above the scan layer of the safety laser scanners create another collision hazard: The vehicles can drag or push such objects away, endangering people. This is why AGVs and AMRs are also equipped with the safeVisionary2 3D time-of-flight camera. It also provides safe, gap-free object detection for the area above the safety laser scanners. This increases personal protection and the availability of AGVs and AMRs.

Book a free consultation with our engineers

About SICK

SICK is one of the world’s leading solutions providers for sensor-based applications in the industrial sector. Founded in 1946 by Dr.-Ing. e. h. Erwin Sick, the company with headquarters in Waldkirch im Breisgau near Freiburg ranks among the technological market leaders. With 60 subsidiaries and equity investments as well as numerous agencies, SICK maintains a presence around the globe. SICK has more than 12,000 employees worldwide and generated a group revenue of EUR 2.3 billion in the 2023 fiscal year. Additional information about SICK is available at www.sick.com.au