Annual Report

“WE MAKE VISIBLE WHAT IS ALREADY THERE”

The Smart Data Solutions team has a two-pronged approach. On the one hand, it is working on building up a portfolio of new customer-specific and data-based services in the Installed Base Services Start-up Initiative – from management of customers’ machinery to full-service contracts to convert plants for the world of Industry 4.0. On the other hand, the same team already markets smart services in the Business Unit Smart Data Solutions, and generates sales with them.

»THE TASK OF OUR START-UP WAS TO IMPROVE TRANSPARENCY IN OUR CUSTOMERS’ SENSOR WORLD WHILE

INCREASING PLANT AVAILABILITY AND PRODUCTIVITY.«

“The task of our Start-Up was to improve transparency in our customers’ sensor world while increasing plant availability and productivity. For this purpose, we develop new solutions and business models,” Max Dietrich, Product and Application Manager Smart Data Solutions, describes the starting point. Where is which sensor in the plant? What state is it in? When is the next service due? What data does the sensor provide? What can one do with these data? How can one use the data to draw conclusions about the future behavior of the machine? What added value can one generate from the data?

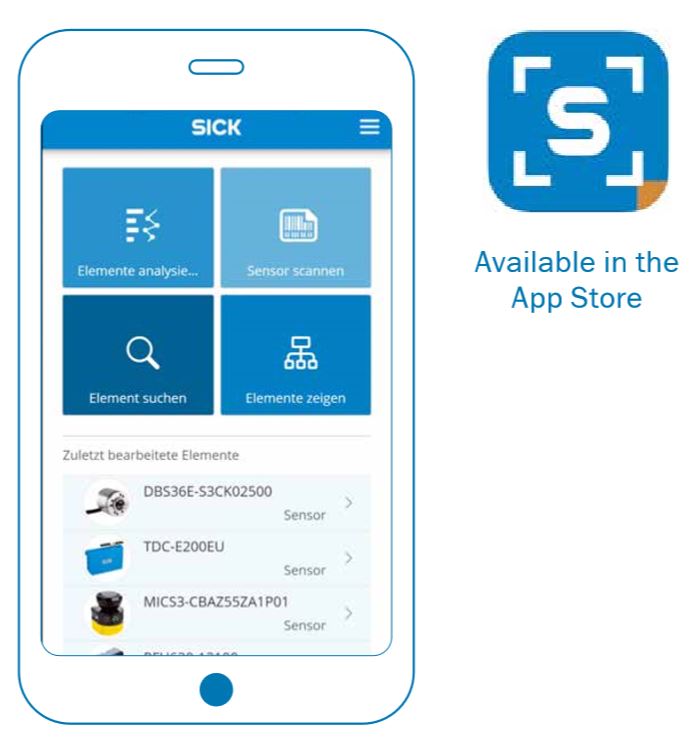

The Start-Up developed a smartphone app to survey the installed sensors and devices, as well as their installation locations. The data thus gained is visualized and supplemented with additional service information, such as maintenance plans, and then displayed in a comprehensible form. Customers can thus optimize the entire maintenance management of their installed base.

ACTION, NOT REACTION

Building upon this basis, one can continuously determine and display the ‘state of health’ of devices in real time by reading out and analyzing data via condition monitoring – and preventive warnings can be issued, if necessary, when predefined limit values are exceeded. “We offer our customers predictive services to prevent critical situations before they occur by developing algorithms – based on the sensor data collected and the customer’s process knowledge – that enable prediction of critical states and their prevention through the use of countermeasures,” Alexandra Schindler, Sales Specialist, Smart Data Solutions, describes the possibilities.

The Start-up Initiative is already developing predictive models for applications with critical environmental conditions, such as those found at ports or waste incineration plants. “In a first step, in collaboration with the customer and experts from the specialist departments at SICK, we create a hypothesis about which factors influence sensor availability. We then examine whether the data support this hypothesis or not. Finally, we develop a predictive model,” explains Max Dietrich. “We have already successfully implemented this at customers,” reports Alexandra Schindler. “Plant availability has now been greatly improved. The customer is better informed, and can react appropriately before a failure occurs. In a waste incineration plant, for example, we can now make a concrete prediction about how long the SICK analyzer will continue to operate properly when wear makes a failure probable. Operators can thus plan their maintenance work more efficiently.”

RECOGNIZING RELEVANCE – DATA BECOME RELEVANT INFORMATION

“The sensor has always had the information. We now make it transparent for the customer,” Max Dietrich sums up. “Together with the customer, and with support from our specialist departments, we work out which of the thousands of variables and parameters are relevant,” adds Alexandra Schindler. Information on the state of production plants – and the accompanying predictions about potential production downtimes made with the help of innovative feedback systems – provides an example of how sensor information can be used to make processes more transparent.

The Start-up Initiative has smoothed the path for smart data solutions with the Installed Base Manager, the service module in the in the SICK AssetHub, the Monitoring Box and Predictive Services.

THE INSTALLED BASE MANAGER

> Back

Imprint | General Terms and Conditions | Terms of use | Dataprotection | © 2024 SICK AG