What is Machine Vision?

Machine vision is a key technology to improve product quality and to optimize the production yield, cost, and throughput. Vision solutions give machines the ability to ‘see’ and take actions to support or replace manual inspections tasks with the use of digital cameras and image processing. The technology is used in a wide range of industries and applications to automate the production process.

Vision solutions are ideal for automated inspection and measurement tasks. SICK’s 2D and 3D vision cameras can be used to solve a wide range of applications where there is a need to measure, locate, inspect and identify. Our vision products are built for industrial environments, carefully designed to leverage SICK's 60-plus years of experience with industrial sensors.

APPLICATION EXAMPLES

Dimension measurement

Machine vision can be used to check quality and dimension

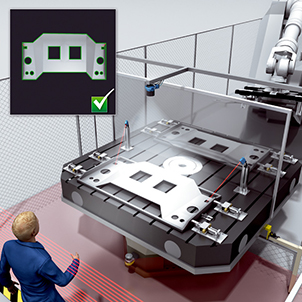

Assembly check

Machine vision instantly identifies incorrectly assembled products, and helps identifying which part of the production line needs checking. No time-consuming trouble-shooting.

Quality assurance

Consistency in product quality is important. With machine vision, you can instantly check everything from assembly to micro-cracks in products.

Positioning

Machine Vision can be used to check the position, orientation and location to ensure that it is correctly placed.

Select the best technology for your vision application

2D/ 3D VISION

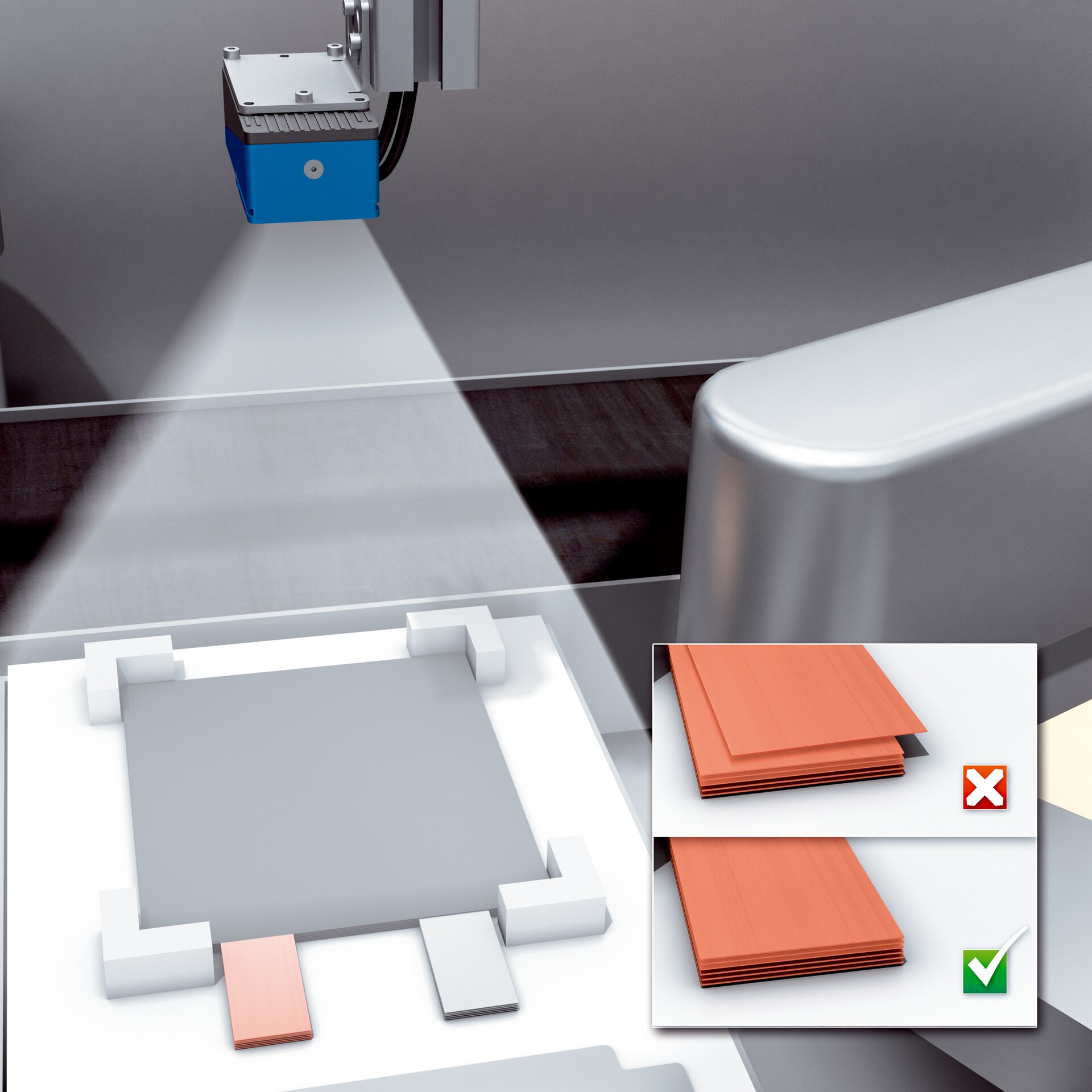

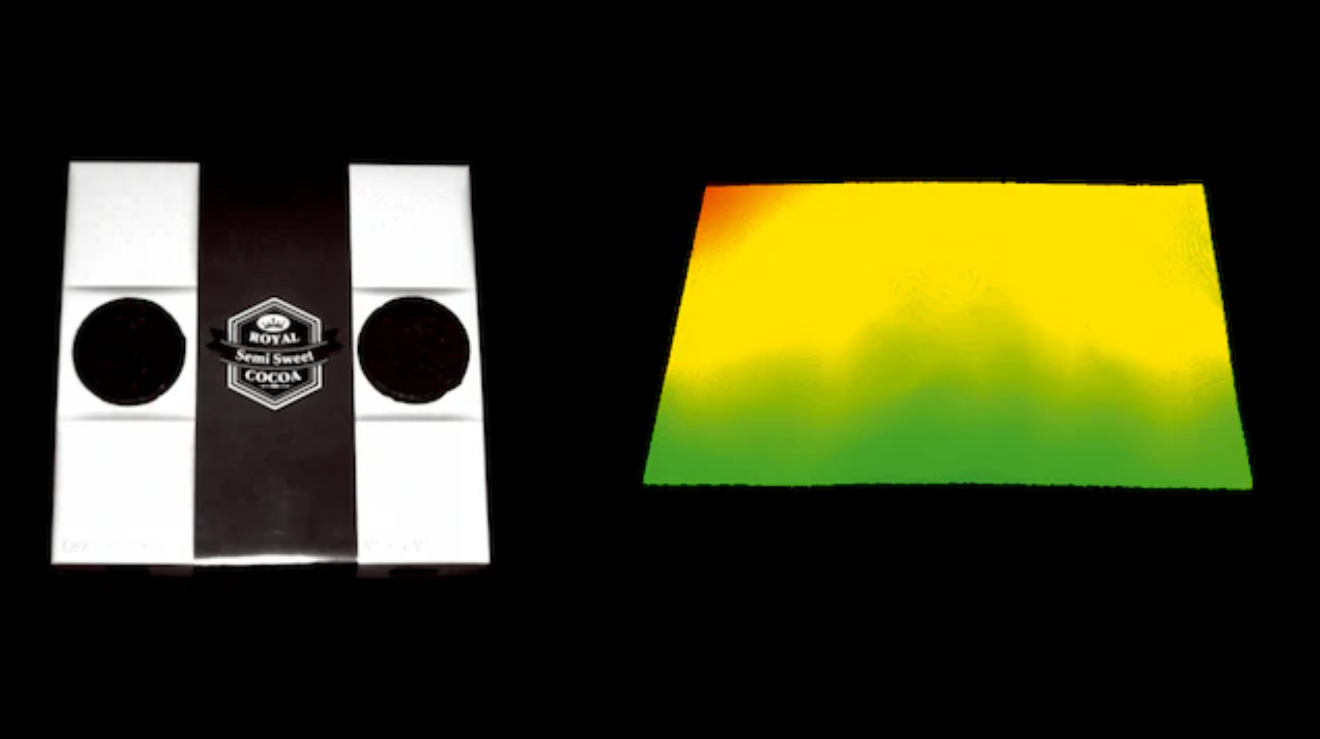

Solving applications in 2D or 3D There are often many possible ways to solve a specific vision task. In some cases, the choice of either 2D or 3D vision is obvious, but in other cases both technologies could work but each provide certain benefits. It is important to understand these benefits and how this applies to a given application in order to provide a reliable machine vision solution

WHAT IS THE DIFFERENCE?

2D Machine Vision

2D is ideal for applications where objects and features can be distinguished by different colors or contrast. It is also perfect for verification of textures, patterns, and codes. 2D vision sensors from SICK are easily configurable to solve a wide range of applications. With added flexibility, solving the most challenging task is easy with functionality that can be extended by programming.

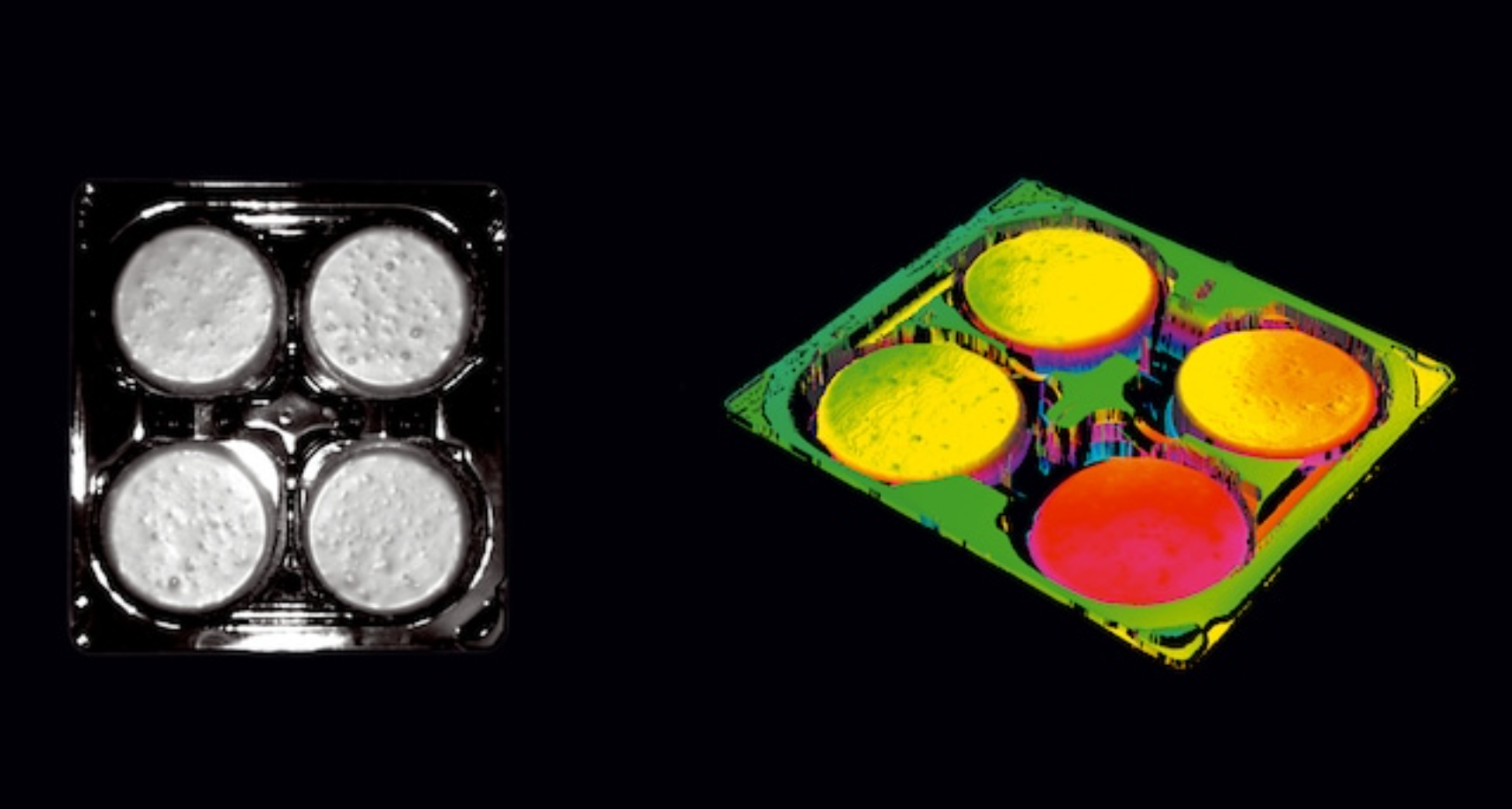

Example of the chocolate box above, 2D is best approach for inspecting box print.

3D Machine Vision

With the third dimension in 3D vision, it adds information about objects’ volume, height, pose, and actual shape. It can also be used to distinguish items of the same color or pattern, thus enabling more reliable solutions. The 3D vision portfolio from SICK covers the full range from powerful high-speed 3D cameras to easily configurable stand-alone 3D vision sensors.

Example of the chocolate box above, 3D vision is employed to precisely measure the stack height of chocolates within a box.

Empowering your business with SICK machine vision solution

Add intelligence and speed.

Arrange a consultation now

Would you like to learn more about machine vision solution? We can answer all your questions in a non-binding consultation.

Our experts are happy to meet with you!

Hear our Favorite Customer Success Stories

Machine vision needs experts: how to achieve complex quality checks

Two things are needed to create highly functional machine vision solutions. The first is top-level expertise in machine vision technology. The second is knowledge of the industry to which that machine vision technology is being applied. These two elements come together in SICK’s Vision Partner Program, which creates close, long-term working relationships for every industry. By combining SICK’s technology, experience and customer-focused service with the machine vision know-how of Delta Systems Kft., it was possible to create the best possible solution for a complex quality check application. Read More

Ranger3 irons out any issues for 3D inspection in steelworks

When it comes to optical 3D inspections in thermal production processes for continuous casting plants, hot rolling mills, and tube rolling mills, flickering surfaces, heat, tinder, dirt, and moisture are all par for the course. But for IMS Messsysteme GmbH as market leaders in precisely this field, handling these challenges is a fundamental aspect of their core skill set. For more than a year now, the company has been using a 3D vision sensor in the form of the Ranger3 from SICK, which significantly improves the performance of its own inspection systems while at the same time opening up new fields of application and business opportunities. Read More

The "sighted" cobot: 2D position determination with robot guidance system

Mitsubishi Electric and SICK have worked together to develop a highly flexible and easy-to-use robot application. The key is a camera combined with special integration software.. Read More