SENSOR SOLUTIONS FOR CONSUMER GOODS

Join SICK at Gulfood Manufacturing 2025 in Dubai!

SICK solutions are at the forefront of transforming the food and beverage industries, addressing the increasing demands for sustainability and digitalization.

By integrating hardware, digital products, and services into the manufacturer’s ecosystem, SICK ensures transparent material flows and seamless logistics processes, extending beyond production.

Discover more at Gulfood Manufacturing 2025, from 4th – 6th of November,

opening hours: 10am – 6pm.

Find us at the Dubai World Trade Centre, Zabeel Hall 1, booth # Z1-16.

We look forward to seeing you there!

Discover our latest PRODUCTS

INSPECTORP61X - COLOR VISION

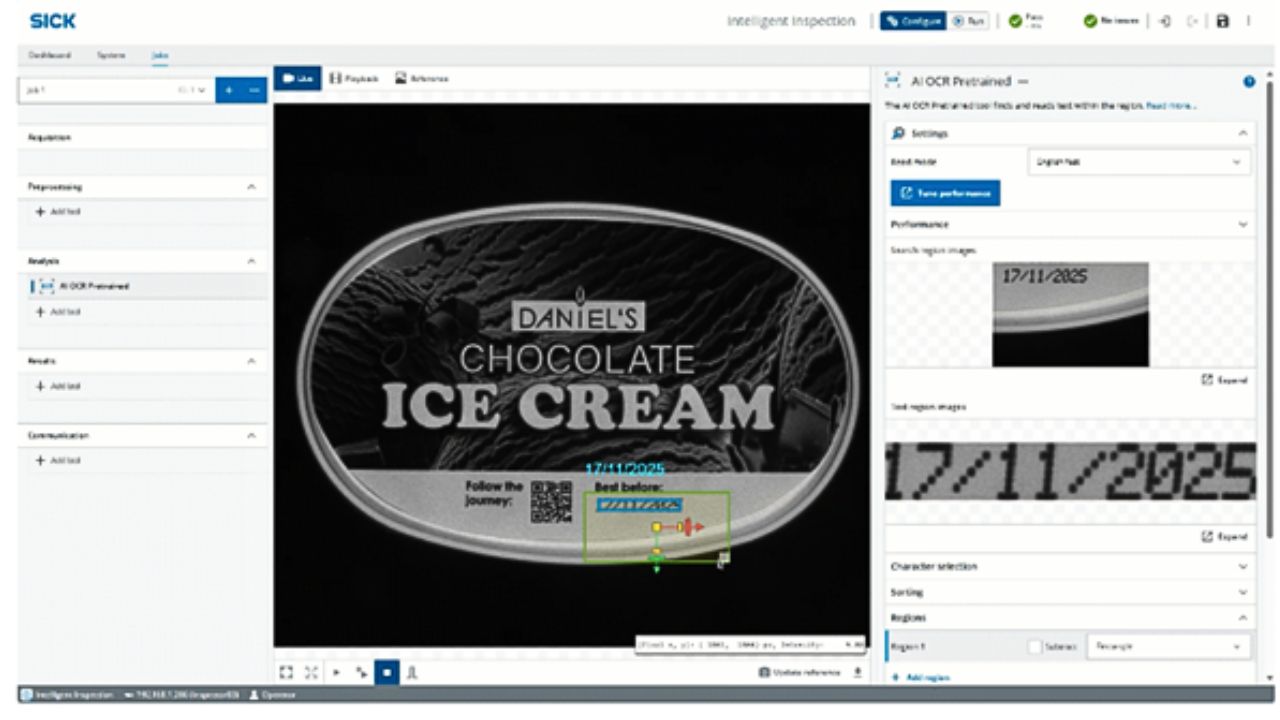

SICK NOVA 2.13 - AI OCR PRETRAINED TOOL - BEST-BEFORE DATE SCANNING

InspectorP61x unlocks new possibilities by inspecting color attributes with precision—perfect for color sorting, defect detection, and top-tier quality control. Whether you need to identify components, recognize materials, detect color markings, verify labels, or assess food quality, color imaging takes your inspection to the next level.

Thanks to SICK Nova's AI-driven features, color data is processed and refined for quicker, more precise decision-making right on your production line.

With the release of SICK Nova 2.13, the AI OCR Pretrained tool now also handles dot print as easy as if it was standard characters - without training or fiddling with settings.

This upgrade revolutionizes quality inspection by combining AI with precise rules, making it ideal for scanning best-before dates.

And solutions for...

1D to 2D barcode Transition in Food & Beverage Operations

The global shift to 2D barcodes is revolutionizing how food and beverage manufacturers manage product data, traceability, and consumer engagement. With the GS1 initiative aiming for full adoption by 2027, now is the time to upgrade your systems and stay ahead.

At SICK, we’re helping manufacturers stay ahead with smart sensor solutions that support GS1-compliant data capture — enabling better visibility, faster scanning, and richer product information. From enhanced data capture to smarter supply chain visibility, we’re here to future-proof your operations.

Safe Material Flow

In the food and beverage industry, safety and efficiency go hand in hand. SICK’s Safe Material Flow solutions ensure seamless, protected transport of goods across automated systems — from raw material handling to packaging and distribution.

With intelligent sensors and TÜV-certified safety systems from entry/exit safeguarding to dynamic muting and access protection, manufacturers can safeguard personnel, maintain hygiene standards, and optimize throughput without compromising productivity.

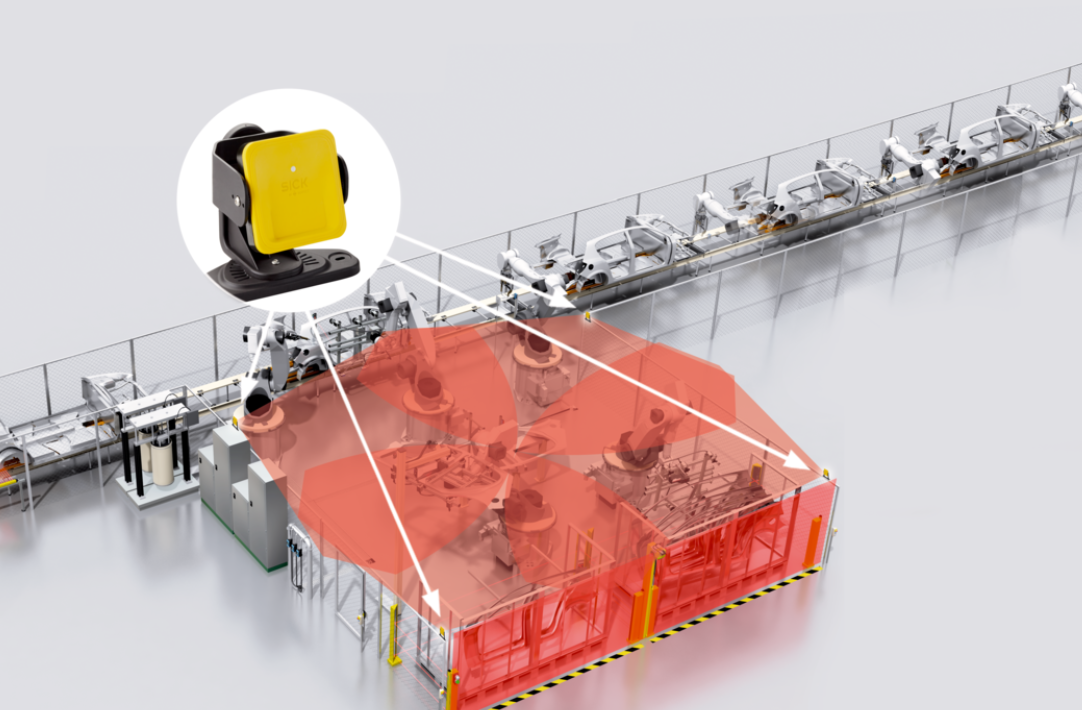

Arial Safe Guarding with safeRS

In the food and beverage industry, maintaining safe and efficient operations is critical — even in challenging conditions like dust, steam, or variable lighting. SICK’s safeRS/safeRS3 radar sensors offer robust area safeguarding with 3D protective fields that reliably detect personnel in hazardous zones.

With PL d / SIL 2 compliance, up to 6 sensors per system, and resistance to contaminants, safeRS ensures uninterrupted safety. Its IP67-rated housing, fast setup, and smart restart interlock make it ideal for automated F&B environments where hygiene, uptime, and protection go hand in hand.