Magazine for the Annual Report

Shaping the energy transition

Solutions from SICK are already used regularly in applications involving hydrogen – and there is still significant potential here. What strategy is SICK pursuing regarding hydrogen applications, and what contribution do the company’s solutions make towards the energy transition?

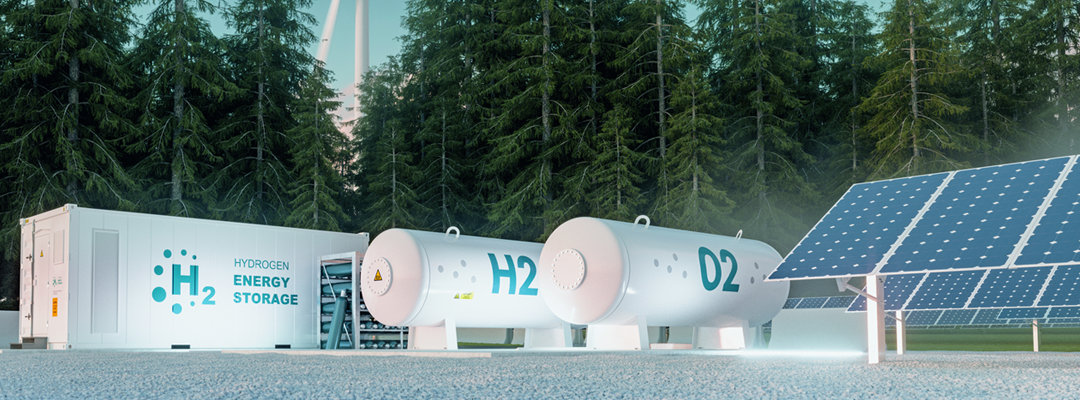

‘Green’ or ‘blue’ hydrogen play a central role in the energy transition and are already being used in many pilot plants as an alternative to CO2-emitting processes – for example in the steel and chemical industries, or in fertilizer production. In future, hydrogen will also be fed into the natural gas network and thus reduce the proportion of CO2 released during burning. For this purpose, in the first phase, hydrogen made using electricity from regenerative resources (via a power-to-gas system) will be used –exploiting excess electricity created when there is a lot of sun or wind, in particular. All these applications involving hydrogen are gaining in importance, and require new solutions from the participating companies.

Solutions for hydrogen applications

Let’s start by looking at adding hydrogen to the natural gas pipelines: In some parts of the world up to 2 percent of hydrogen can already be added to natural gas. It is assumed that this figure could rise to between 15 and 30 percent in future. Research is being carried out on this because many aspects must be taken into account regarding the design and operation of gas measurement and control stations. This is because hydrogen influences the density, viscosity, explosiveness, flow properties, and sound velocity of the gas mixture. The service life of an entire pipeline is also affected. This imposes completely new challenges on the pipes, compressors, seals, and valves, etc. And the gas flow counters must also accurately and reliably measure the natural gas/hydrogen mix. SICK’s FLOWSIC devices can already do this. The team at SICK’s Ottendorf-Okrilla site near Dresden has intensively tested how the added hydrogen affects the ultrasound technology of FLOWSIC devices: “Our devices already measure hydrogen-bearing natural gas as reliably and stably as natural gas without hydrogen,” says Jörg Wenzel, Head of Product Marketing Services and Flow Measurement. The device can compensate for any measurement uncertainties.” SICK has even already developed a solution for a proportion of up to 30 percent. This is necessary because the hydrogen – with its low density – strongly increases the speed of sound in pipelines: “The new dynamics in the plants, in particular, are challenging. Almost no hydrogen is fed in when there is little sun and wind. On the other hand, the proportion of hydrogen can rapidly increase when there are excess renewable energies. Such strong fluctuations are new for the gas infrastructure. The ultrasonic technology of our gas counters is particularly suitable for these rapidly changing process conditions,” explains Wenzel. “We measure both small and large flow quantities very accurately.”

Start-up for the environment

The second major area of application for SICK solutions involves the generation, transport and industrial use of pure hydrogen: The quantity and quality of the gas must be measured along the entire hydrogen network – a business field with enormous potential, and one that SICK is in the process of opening up. The prerequisites for this are good: “We are the world market leader in legal-for-trade measurements of natural gas using ultrasound gas counters. Our ultrasound flow measurement technology is fundamentally also suitable for applications involving pure hydrogen,” adds Frank Hehl, Senior Vice President Global Industry Center Process Automation. The high speed of sound in pure hydrogen is a challenge: The measurement times are in the nanosecond range in low-diameter pipelines. “For this purpose, we are currently working on completely new electronics that we are testing in practical use in collaboration with our customers, and we want to further develop it so that we can rapidly reach market maturity and secure a significant market share,” explains Hehl. “The measurement of purity is another important market segment. Determining the quantity and quality in a system is a real competitive advantage.”

SICK has underlined the importance of expanding these activities by founding a start-up within the company to explore the new market potential and identify possible applications involving hydrogen measurement. “Given the numerous possible options, this approach is principally intended to rapidly identify lucrative business opportunities and develop attractive solutions in collaboration with our customers,” says Hehl. “We have the expertise and a unique opportunity to combine our commercial success with helping achieve a low-CO2 future.”

"The retention, storage, and use of CO2 is indispensable for climate protection"

Carbon capture, utilization and storage (CCUS) technology is used to separate CO2 from certain industrial processes and make it harmless. But the method is not uncontroversial. Aurélie Moll, Technical Industry Manager Carbon Capture Utilization and Storage, explains why we nevertheless need CCUS to achieve the climate goals – and what SICK can contribute.

Ms Moll, how exactly does carbon capture, utilization and storage function?

Mankind has emitted immense quantities of CO2 since the start of the industrial age – with well-known consequences. And worldwide energy requirements are increasing inexorably. Although electricity from regenerative sources is gaining in importance, the path to ‘green’ energy is still long and will only be completed gradually – from the current coal, through natural gas, to hydrogen, the energy carrier of the future. But we cannot wait any longer. Carbon capture, utilization and storage is now an effective possibility for making at least some of the greenhouse gas ‘harmless’: The CO2 that is emitted by certain industrial processes and power stations can be separated directly on site. Separation rates of up to 90 percent can be achieved. Then the CO2 is reused by converting it into other products with a greater commercial value, such as synthetic fuels or plastics, while maintaining overall carbon neutrality. Or the CO2 is stored deep underground, for example in empty gas fields. It is important to understand that both approaches can bind CO2 emissions from familiar industrial processes.

But it would be a lot better not to emit the CO2 in the first place...

Yes, but in many sectors we cannot be completely emission-free at present, and emissions cannot be avoided at all in certain industrial applications, for instance cement production. The CO2 emitted here is relatively pure and can therefore be ‘captured’ very easily and reused or stored. CCUS is therefore a very good solution for making such unavoidable emissions harmless for the climate.

The sector is already working on solutions for ‘green’ cement, i.e. produced climate-neutrally.

Das Verfahren wird aber auch durchaus kritisch gesehen. Zu Recht?

Natürlich ist CCUS nicht die Lösung für die Klimakrise. Die Notwendigkeit, CO2-Emissionen nach Kräften zu vermeiden, besteht weiterhin. Aber die Technologie ist – auch, was unterirdische Lagerung des CO2 anbelangt – sicher. Aus allen diesen Gründen ist CCUS ein wesentliches Element in den Szenarien vieler Experten und namhafter Forschungsinstitute, etwa der Internationalen Energieagentur. Auch wir bei SICK sind davon überzeugt, dass das Binden, Lagern und Nutzen von CO2 für den Klimaschutz unverzichtbar ist. Denn, das kann man nicht genug betonen: Uns läuft die Zeit davon, wir müssen handeln. Und Carbon Capture ist eine Technologie, die eben schon heute auf bestehende Anlagen über Nachrüstungen angewendet werden kann und auch neue großtechnische Anlagen ergänzt. Deshalb wollen wir uns hier mit unseren Lösungen noch stärker einbringen – auch wenn das aufgrund von Kritik am Verfahren eventuell auf den ersten Blick nicht nachvollziehbar ist.

But the process is also heavily criticized. Justifiably?

Of course CCUS does not solve the climate crisis. We still need to avoid CO2 emissions as far as possible. But the technology is safe, including the underground storage of CO2. So for all these reasons CCUS is an important component in the scenarios of many experts and well-known research institutes, such as the International Energy Agency. We at SICK are also convinced that binding, storing and reusing CO2 is indispensable for climate protection. Because, and one cannot stress this enough, we are running out of time – we have to act. And carbon capture is a technology that can already be applied to certain plants by retrofitting them, and it will also be installed in new industrial plants. That’s why we want to get more involved here with our solutions – even if this may not seem to make much sense at first glance, given the criticism of the process.

What solutions does SICK offer for CCUS applications and technologies?

Carbon dioxide is emitted from a variety of sources, collected and transported via pipelines or ships for further processing, such as storage or utilization. We already offer gas analysis devices that monitor process and emission parameters for the separation process in the CO2 scrubbing plants. Gas flow measurements are required for the subsequent transport of the pure CO2 at every transfer point: The quantity and quality of the gas, and any impurities it may contain, must be monitored – to protect health and the environment, as well as to guarantee accurate invoicing with the companies, or the calculation of CO2 levies and credits. SICK already has solutions that support these CO2 transport applications. Some of our FLOWSIC models are already suitable for use in CO2 pipelines, and measure the exact gas quantity at every transfer point in the pipeline. The next step is to further develop our products so that they are also suitable for quality assessment and, for example, can detect any traces of water that could have a corrosive effect on the pipes. So CCUS offers many potential areas of application for our sensor solutions. We see great potential for this technology – for us as a company, but also for climate protection.